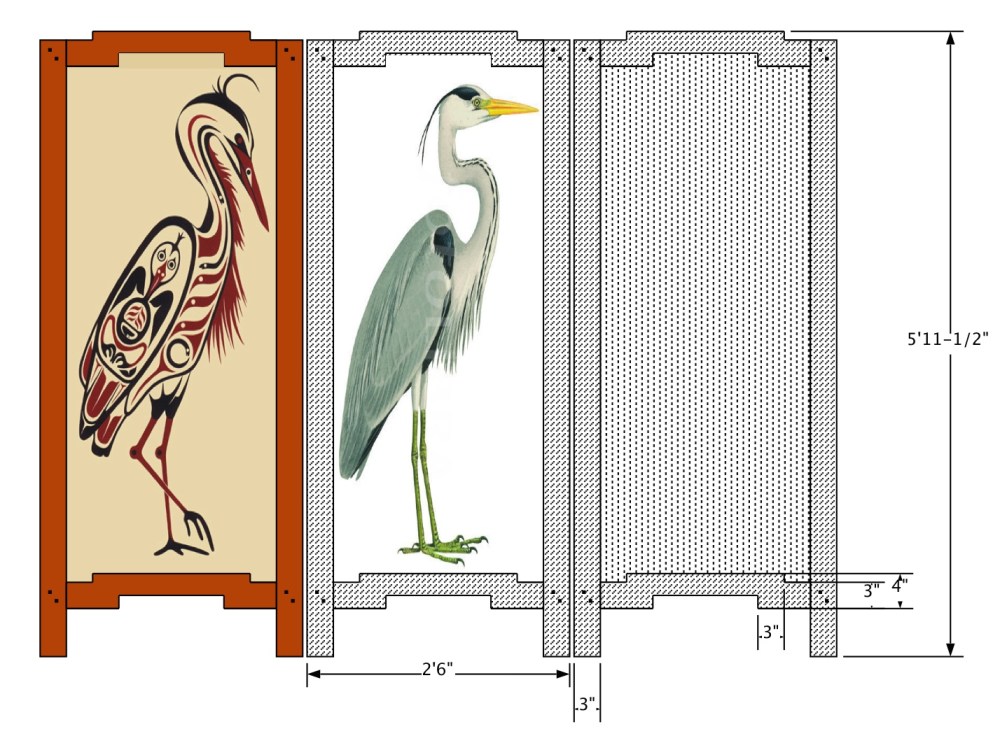

Well, it’s finally done, the privacy screen project came out better than expected. It’s framed with lye washed cherry, the infill is douglas fir, and it’s accented with gaboon ebony plugs. There’s even a turquoise infill in a check at the bottom of one of the stiles.

It’s 6′ tall, and tonight I discovered that it doesn’t fit in the display window because when I built the platform for the window, I measured for 6′, but forgot to allow for the carpet thickness. That’s not so bad, but when I went back to my original plan, I noticed that it said 5′ 11 1/2″. I’m sure that I said, “That’s dumb, why would I do that?”, and then proceeded to make it 6′ tall. 😕 🙄

So, it sits behind the platform, but in front of the curtained backdrop. Kris thinks it works even better that way because it shows off the tops better. I’m just glad that it fits at all now.

Cheers,

Tom